sales[at]leblansch.com

sales[at]leblansch.com  0229 820 236

0229 820 236

Factors to consider when selecting a diverter valve:

Selecting a diverter valve for your pneumatic conveying system can be a tough job, especially when it comes to considering how many diverter valves are on the market. Yet a properly selected diverter valve can keep your operation running smoothly, cut maintenance costs, and improve your conveying system’s efficiency. After outlining factors you should consider to select a diverter valve for your system, this article provides descriptions of commonly used diverter valves, how they work, how they’re applied, and their pros and cons.

Before you can select a diverter valve for your pneumatic conveying system, you need to consider several factors: your application type, your conveying system type, your material characteristics, valve cost, and valve options.

Application type – Most diverter valves, also called two way diverter valves, convey material from one source to two destinations. In some applications, a two-way diverter valve is installed backward in the line to convey material from two sources to one destination. When used this way, it’s called a two-way converger valve. However, be aware that turning a conventional two-way diverter valve into a converger valve may require the manufacturer to make costly design modifications that will increase the valve’s purchase price. It may be more practical to select a valve specifically designed for converging.

If your system has more than two material sources or destinations, you need to consider how each diverter valve can be installed to meet your system’s design criteria, as well as, your budget. One way to meet these constraints is to install a diverter valve with more than two ports, called a multiport diverter valve.

Conveying system type – Your diverter valve choice will depend on whether your pneumatic conveying system is dilute- or dense-phase and operates under pressure or vacuum. A dilute-phase system can have a conveying line pressure up to 15 psig or vacuum pressure down to 30 inches mercury, while a dense-phase system can have a conveying line pressure up to 90 psig. Make sure the valve you select will operate well in your conveying phase and at your system pressure or vacuum.

You also need to consider your pneumatic conveying system’s pressure or vacuum capabilities and line diameter, as well as the expected pressure drop across the valve, to help determine the valve’s minimum and maximum size. This ensures that the valve will function properly and efficiently after it’s installed in your system. To help you narrow the field, many manufacturers pressure-rate each of their valves and provide a valve-sizing chart listing each valve’s specifications and limitations.

Material characteristics – Consider your material’s characteristics, such as particle size and abrasiveness, to choose a diverter valve that can handle them. Particles that are too large for the valve you select

can become jammed between the diverter’s internal components, preventing the valve from fully closing off the specified downstream conveying line or lines (the closed line or closed lines) to air and material flow. Particles that are too small for your valve can become packed between the internal components, binding the diverter, or the material can pass into the closed line.

Material that’s too abrasive for your valve’s design can erode the valve components, creating a gap for air and material to pass through into the closed line. Air passing through this gap will create a pressure drop across the system that affects the system’s capacity and material passing through to the closed line may contaminate your finished product.

To fix these problems, you must shut down the conveying system and remove the valve to either clean or replace its internal parts. This creates lengthy production downtime, increases maintenance and production costs, and reduces your system’s efficiency. To prevent these problems, identify your material characteristics and choose a valve that can handle them.

Cost – A diverter valve’s purchase price is only one of many costs you need to consider. Others include shipping, installation, and maintenance costs, material cross-contamination costs associated with internal valve leaks, and lost-production costs caused by maintenance downtime. You can discover these and other performance-related costs by asking for information from users who have installed a particular valve in an application similar to yours.

Options – Depending on your material characteristics, you can specify that a diverter valve and its components be constructed of cast aluminum, cast iron, stainless steel, or a specialty alloy. And depending on your pneumatic conveying system’s specifications and power availability, you can often specify that a valve be actuated manually, by air, or by an electrical motor. You can also specify a valve with an air-controlled solenoid and position indicating switches.

Now, keep these selection factors in mind as you explore the types of available diverter valves. The following information covers five common diverter valves: rotary-plug, rotary-blade, flapper, sliding-blade, and flexible-tube. Multiple-source, multiple destination diverter valve configurations are also discussed.

Valve Size: 6″

Handling: Pebble Lime

Location: Steel Mill in the state of Washington.

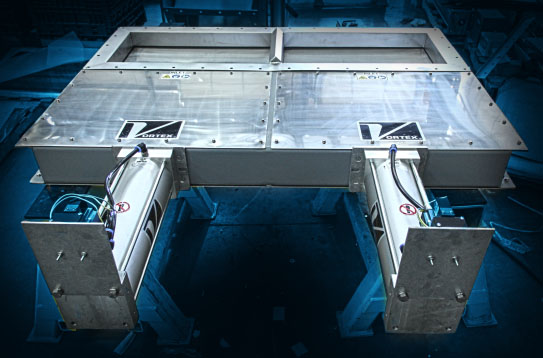

Features: Vortex 2-way and 3-way Mainline Diverters are fabricated from Vortex TPV slide gates. The gates are connected by a ceramic coated weldment made of sch 80 carbon steel pipe.

Why: TPV gates were chosen due to the abrasiveness of the material being handled. Multiple gates allow individual control of each discharge port.

Customer: Pet Food Manufacturer

Material: Dry Granular Pet Food

Application: Start and stop flow of material into a ribbon mixer below a drag chain conveyor.

Challenge: Special service inlet with hat section over the common side frame prevents material from collecting.

Valves: Two independent Roller Gates sharing a common side frame with two 16×30″ blades and special service inlets.