sales[at]leblansch.com

sales[at]leblansch.com  0229 820 236

0229 820 236

Wye Line Wisselklep Pneumatisch transport

Vacuüm en dunne fase Pneumatisch transport systemen

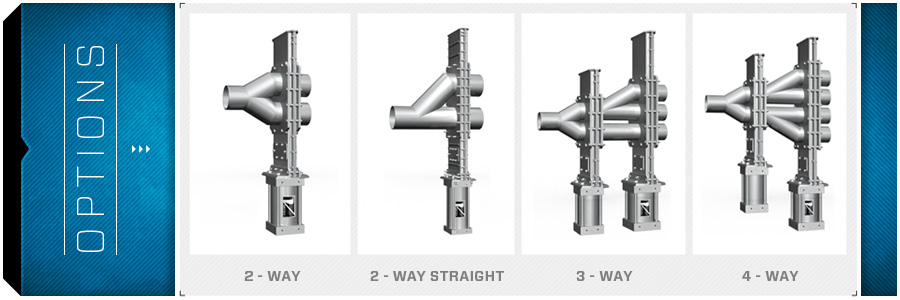

De Vortex Valves Wye Line wisselklep voor pneumatisch transport systemen in 2-weg, 3-weg of 4-weg uitvoering. Geschikt voor transport van goedlopende poeders of granulaten in een vacuüm en dunne fase pneumatisch transport systeem met een werkdruk tot 1 bar (afhankelijk van de doorlaat), voor het verdelen van 1 naar 2 transportlijnen of van 2 naar 1, minimaal drukverlies, lucht en product dicht naar de afgesloten poort en naar buiten.

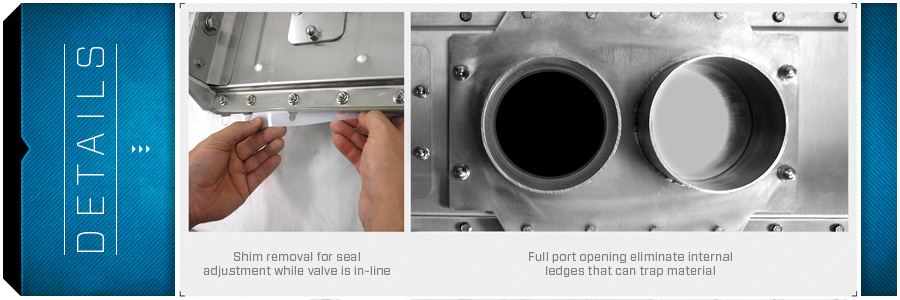

Door het unieke ontwerp van de wisselklep is het mogelijk om te schakelen in productstroom zonder het afsluiten van de productstroom of lucht toevoer en is de wisselklep mechanisch zelfreinigend na elke cyclus. Uitwisselbare slijtdelen, afdichting kan na-gesteld worden zonder de wisselklep uit het systeem te halen.

Hoge stand tijd door toepassing harde duurzame polymeren afdichtingen volgens EG1935/2004. Atex volgens 94/9/EG zone 20.

Kenmerken Wye Line Diverter

- Geschikt voor poeders, granulaat, pellets

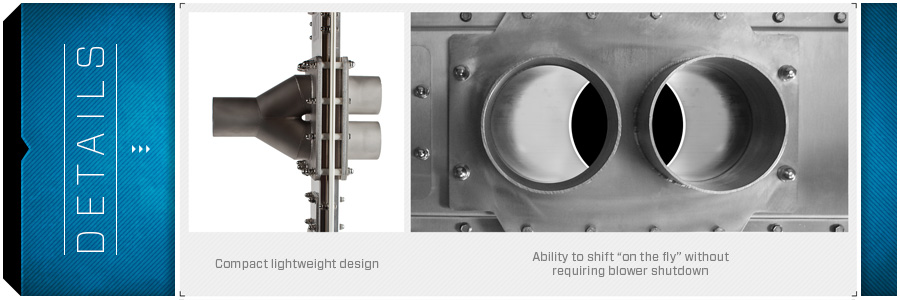

- Schakelen in productstroom “Shifts on the fly”

- Hoge stand tijd door polymeren afdichtingen volgens EG1935/2004

- Volle product doorgang zonder open hoeken

- Afgesloten poort is vacuüm/druk dicht tot 1 Bar

- Toepassing voor zowel divergeren en convergeren

- Afdichting kan “in-line” na-gesteld worden

- Leverbaar in 2-weg, 3-weg, en 4-weg uitvoeringen

- Constructie delen uit Aluminium, Staal, RVS304 of RVS316L

- Standaard doorlaat van 50 tot 300mm

- Atex volgens EG richtlijn 94/9/EG zone 20

Technische Informatie

| Specifieke kenmerken | |

| 2” to 12” Pipe or Tube (2″ to 6″ Pipe or Tube on 3 and 4-Way) | |

| Powder, Pellets, Granulars | |

| ANSI, DIN, JIS, or Compression Couplings | |

| 180°F (82°C) for standard gate with modifications allow up to 400°F (204°C) | |

| Up to 15 psig, 1 barg (depending on size) | |

| 304 or 316L Stainless Steel, Aluminum, and/or Carbon Steel | |

| 304 or 316L Stainless Steel, Aluminum, and/or Carbon Steel | |

| Nylon, PET, UHMW, Glass Filled Teflon, Natural Rubber, and/or Silicone Rubber | |

| Double Acting Air Cylinder and Solenoid Operated Air Control Valve, Electric Actuator, Chain Wheel, Hand Wheel | |

| Magnetic Reed, Proximity, or Mechanical Limit Switches | |

| CE, ATEX, FDA | |

| Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles | |

| Opties | |

| Material / metal contact is 316L stainless steel. | |

| Diverter has straight through conveying line designed for easier “in line” installation and less system conveying pressure drop when using multiple diverters. | |

| Standard tube size diverters are made with schedule 10 pipe throughout. | |

| Standard tube size diverters are made with schedule 40 pipe throughout. | |

| Modifications are made allowing 250°F (121°C) continuous to 300°F (149°C) intermittent service. | |

| Modifications are made allowing 400°F (204°C) continuous to 450°F (232°C) intermittent service. | |

| Gate blade is electropolished. Polyethylene (PET or UHMW) pressure plate seals are used to replace nylon. | |

| Inlets and outlets are flanged with ANSI, DIN or JIS connections. The outlet opposite the air cylinder is offset at 30 or 45 degrees. | |

| Toepassing | |

| Gravity flow or dilute phase pneumatic conveying (pressure or vacuum) |

| Handles non abrasive to moderately abrasive powders, granules and pellets |

| Horizontal or vertical valve orientation |

| Open / closed or volume metering of material |

| Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles | |

| Voordelen | |

| Ordinary flapper-style diverter valves rely on elastic seals which are exposed to blast abrasion causing them to erode and tear away in service. The Wye Line Diverter is designed so the seal plates are shielded from blast abrasion providing long, reliable service. |

| Rotating tunnel diverter valves typically have seals which are exposed to excessive wear upon actuation and are prone to seizing and binding due to material buildup between the plug and the housing. The Wye Line Diverter is self-cleaning on each actuation and is designed for high cycle service. |

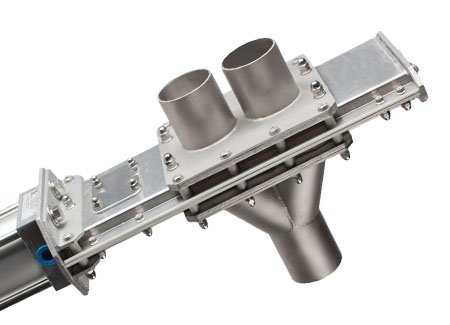

| Traditional cast iron diverter valves are heavy and bulky, increasing their installation costs. The compact design and low weight of the Wye Line Diverter is advantageous when installation is required in crowded or overhead equipment areas. |

| The Wye Line Diverter offers positive sealing in both vacuum and pressure conveying systems. The scissor material shearing action allows the valve to reliably diverted on a stream of material (when required). |