sales[at]leblansch.com

sales[at]leblansch.com  0229 820 236

0229 820 236

Aggregate Diverter – Wisselklep

Gravity Flow Conveying

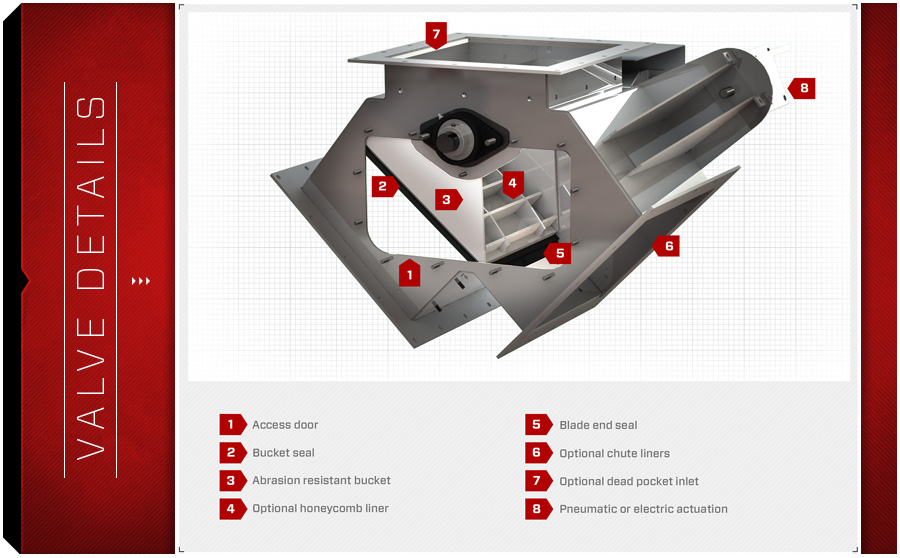

The Vortex Aggregate Diverter is designed to meet the demanding applications with handling material such as sand, gravel, whole grains, and coal. The optional inlets, chute liners, and bucket liners extend the life of this valve when handling abrasive materials. The diverter’s access panel allows for quicker entry to the interior of the diverter for inspecting and cleaning the valve. The heavy-duty abrasion resistant bucket is also removable through this access panel for service.

Kenmerken Aggregate Diverter

- Handles sand, gravel, whole grains, and coal

- Optional replaceable abrasion resistant liners

- Heavy-duty bucket that addressees material impact and wear

- Removable access door for internal inspection, cleaning, and maintenance

- Bucket seals reduce interior dusting

- Serviceable while in-line

- Optional interior dead-pockets allow material to impact on itself reducing wear

- Optional return pan prevents dusting to atmosphere

Technische Informatie

| Specifieke kenmerken | |

| 6” to 24” Square or Rectangular with Round Transition options | |

| Aggregates | |

| SVC Standard Flange, ANSI, DIN, JIS, or Custom Flanges | |

| Up to 250°F (121°C) continuous to 300°F (148°C) intermittent service, modifications allow up to 400°F (204°C) continuous to 450°F (232°C) intermittent service | |

| 0 psig, Gravity Flow Only | |

| Carbon Steel | |

| Carbon Steel | |

| Polyurethane, EPDM, and/or Silicone Rubber | |

| Double Acting Air Cylinder with Solenoid Operated Air Control Valve, Electric Actuator, or Hand Lever | |

| Magnetic Reed, Proximity, or Mechanical Limit Switches | |

| CE, ATEX | |

| Agriculture, Chemicals, Minerals, Mining, Petrochemicals, Plastics, Textiles | |

| Opties | |

| The angle the outlets are offset (45 or 30) degrees. | |

| Modifications are made allowing 400 F (204 C) continuous to 450 F (232 C) intermittent service. | |

| Carbon steel special service inlet with built-in dead pocket deflector. | |

| Replaceable abrasion resistant polymer liner on bucket legs. | |

| AR400 carbon steel honeycomb liner on bucket legs. | |

| AR 400 carbon steel honeycomb liner on bucket. | |

| Round transitions with SVC bolt hole pattern are mounted to the inlet and two outlets of the valve. | |

| Round transitions with ANSI (or DIN if a Metric Valve) bolt hole pattern are mounted to the inlet and two outlets of the valve. | |

| Toepassing | |

| Gravity flow |

| Handles nonabrasive to abrasive materials like Coal, Gravel, Sand, and Whole Grains |

| Carbon steel material of construction |

| Key Industries Served: Agriculture, Chemicals, Minerals, Mining, Petrochemicals, Plastics, Textiles | |

| Voordelen | |

| Traditional bucket diverter designs subject the bucket and diverter internals to excessive wear. The Vortex Aggregate Diverter incorporates two styles of special service inlets to minimize bucket abrasion. Abrasion-resistant polymer chute liners are utilized to minimize chute wear. |

| Most bucket diverters do not provide a positive material seal across the closed chute. Gaps between the bucket and chute allow leakage into the “closed” trunking. Innovative durable rubber bucket seals in the Aggregate Diverter provide a positive material seal at the leading edges of the bucket. |

| The ability to perform maintenance on your valve while in service is a major benefit of this valve. Numerous diverters require removal that causes system downtime. Typically, worn diverters are scrapped rather than repaired resulting in costly equipment replacements. The Aggregate Diverter has a removable access panel allowing for inspection or maintenance of the diverter without removal from service. Replacement of the bucket assembly, polymer chute liners and special service inlet can be accomplished through the access panel opening. |